Our Capabilities:

- Pump, Motor, Valve & PTO Refurbishment

- Winch & Gearbox Repair

- Hydraulic Cylinder Repair

- Hydraulic Cylinder Manufacturing

- Mobile Equipment Service

- Remanufacture & Retrofit Existing Equipment

- Hydraulic Power Units & Controls

- Custom Machining & Fabrication

- Industrial Hard Chrome Plating

- Mobile Service

- Preventative Maintenance Contracts

- Service Exchange Program

Remanufacture & Retrofit Existing Equipment:

To compete effectively in the global market space manufacturers require their equipment to operate at maximum efficiency, precision and accuracy. Manufacturers must also take advantage of the latest in technology to optimize performance and minimize down time.Action Hydraulics has the capabilities to repair or rebuild a wide range of industrial machinery and manufacturing equipment. We are equipped to work on most makes and models of domestic and off-shore built equipment.

Hydraulic Presses:

We specialize in maintaining, rebuilding and retrofitting large hydraulic presses and have been serving the automotive and plastics industries in this capacity for more than 30 years. We can aid your company in deciding on the services that are needed to meet your manufacturing requirements and goals.

At Action Hydraulics, both repair and refurbishment projects follow a standardized process of disassembly, inspection and engineering of the required parts and components. Our inspection process detects wear, cracks and flaws in dimensional integrity. Ultimately our clients are provided an inspection report and are informed of any findings that might result in a change in project scope and cost.

The nature of hydraulic press repair often involves weld repairs on cast iron, cast steel or fabricated steel parts. Welding is a very technical discipline and throughout the years of our operation we have refined our procedures to provide the highest quality welding services in the hydraulic equipment repair industry.

Because hydraulic press components that have been welded eventually require machining to bring them back to size and square, we have also developed the capabilities and facilities to face the challenges of machining parts that have been welded.

In addition to repairing existing parts, we are also fully capable of manufacturing entirely new replacement parts. The method of fabrication can be custom tailored to the specific design and function of the press. All parts can be machined to customer specification or engineered sizes.

Our facility is large enough and well equipped enough to accommodate all rebuilding processes, up to 500-ton presses. Our standard procedure requires that all repaired parts be checked for size and quality before assembly begins. Therefore rebuilt presses can easily be test run in our plant before final customer test and acceptance.

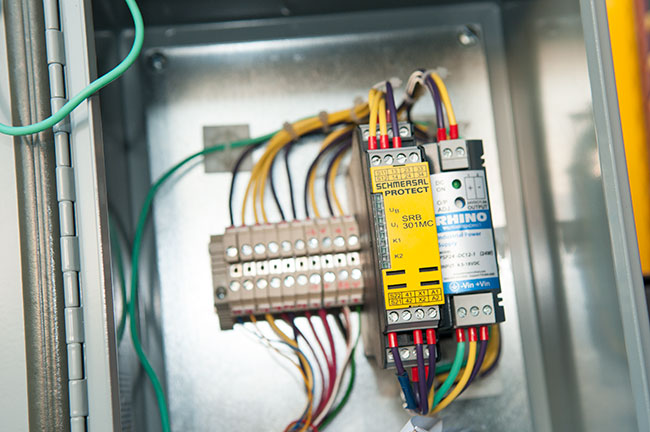

- (Machine guard safety interlock system, designed, and installed to meet upgraded safety regulation)