Our Capabilities:

- Pump, Motor, Valve & PTO Refurbishment

- Winch & Gearbox Repair

- Hydraulic Cylinder Repair

- Hydraulic Cylinder Manufacturing

- Mobile Equipment Service

- Remanufacture & Retrofit Existing Equipment

- Hydraulic Power Units & Controls

- Custom Machining & Fabrication

- Industrial Hard Chrome Plating

- Mobile Service

- Preventative Maintenance Contracts

- Service Exchange Program

Industrial Hard Chrome Plating:

Action Hydraulics owns a modern, chrome plating facility complete with grinding and polishing equipment. This vertical integration, coupled with economies of scale, allows us to deliver repairs and remanufacturing work to our customers faster and more cost effectively than the competition.

Action Hydraulics owns a modern, chrome plating facility complete with grinding and polishing equipment. This vertical integration, coupled with economies of scale, allows us to deliver repairs and remanufacturing work to our customers faster and more cost effectively than the competition.The porous nature of hard chrome translates into it having an excellent lubricating value. Its lubricating value, coupled with the fact that it is extremely hard (measuring 68-72 Rockwell), means hard chrome plating lends itself well to hydraulic applications.

Our technicians employ hard chrome plating in fluid power applications to restore worn parts to their original size and shape, to provide resistance to abrasion, and to protect from corrosion that results from environmental factors.

We routinely carry out a variety of hard chrome plating and coating requirements including but not limited to:

- Hydraulic cylinder rods

- Valve spools

- Plungers

- Piston rings

- Tools and dies

- Printing wear roll surfaces

- Motor shafts

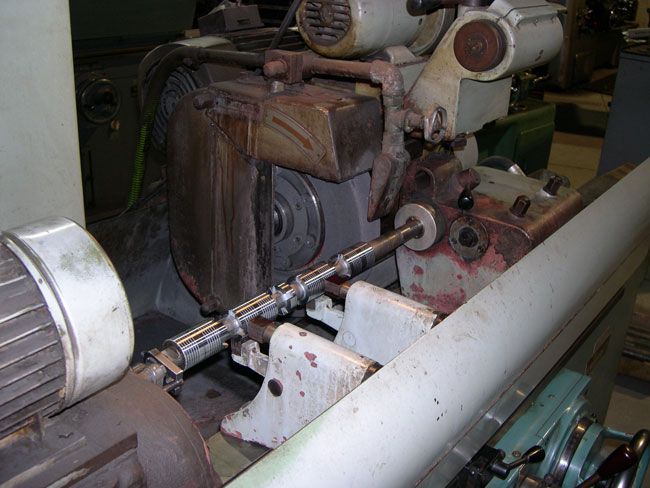

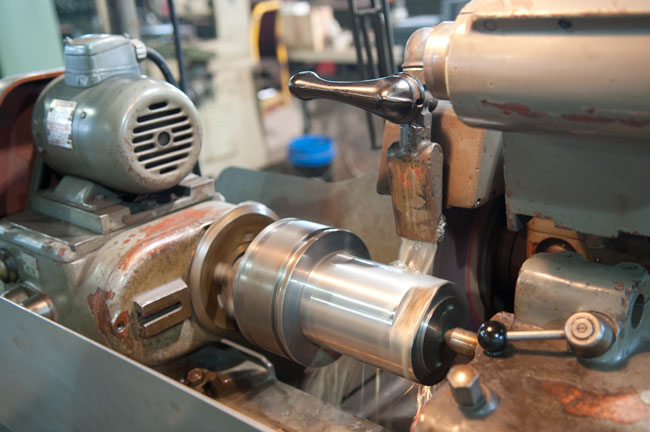

Where it is more economical to do so, or where extreme precision is required, cylinder rods are repaired through a process of grinding and chroming. Essentially, rods are ground undersize, chrome plated oversize and then reground to specification and polished. All dimensions are double checked before rods are delivered to the component repair shop for cylinder reassembly. We also often repair valve spools and pump shafts using a similar procedure.

- (Grinding of a control valve spool)

- (Grinding of a cylinder rod)

- (Chromed cylinder guide pins prior to final grinding stage)

- (Cylinder shell inside diameter honed, chromed and finished honed to specified tolerances)